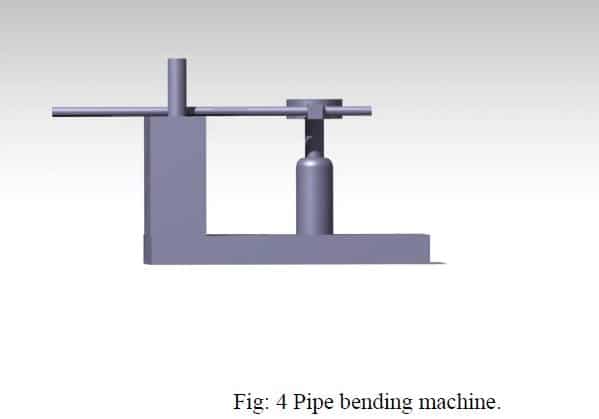

As industries grow, the demand for customized and precise pipe bending services increases. Pipe bending is the process that involves the creation of various shapes for metal in a single unit, used in different pipelines and other mechanical constructions. This type of service usually applies to raw materials such as round tubes, square or rectangular tubes, and profiles.

While traditional pipe bending involves hot deformation, which requires heat treatment and surface finishing, the cold deformation process offers many advantages. Here we will discuss the benefits of cold deformation, and one particular product that improves the column reinforcement process called the easy-install column reinforcement plate.

What is Cold Deformation?

Cold deformation, or cold bending, is the process of bending metal without the application of heat. Instead of heating up the material, cold deformation relies on the use of pressure and force, producing a more consistent, clean, and accurate end product. The cold deformation process can be done with various techniques such as rotary draw bending, compression bending, and roll bending.

The Advantages of Cold Deformation

1. Quality control: Due to its precision, cold deformation reduces the need for heating and finishes, which can damage the surface and texture of the material. Moreover, cold deformation creates a smooth and uniform bend in the material without losing its strength and integrity.

2. Versatility: Cold deformation is applicable to different types of metals such as copper, steel, aluminum, and stainless steel, producing high-quality products that can be used in various industries such as aviation, shipbuilding, automotive, and construction.

3. Sustainability: Cold deformation is an environmentally-friendly process where no harmful chemicals or emissions are produced during the operation. This process also reduces the overall energy consumption by eliminating the need for heating and other finishing treatments.

4. Time and cost-efficient: Cold deformation saves time and money as it requires fewer materials and equipment, decreases the production cycle, and reduces labor costs.

Introducing the Easy-Install Column Reinforcement Plate

Column reinforcement is a crucial process in construction that involves preventing buckling or collapse of concrete columns. In traditional reinforcement methods, the reinforcement plates are placed manually, which is a time-consuming and labor-intensive process.

Luckily, there is an innovative solution to this problem – the easy-install column reinforcement plate. This product is a pre-fabricated reinforcement plate that allows for quick and easy installation, reducing the time and cost for column reinforcement significantly. The easy-install column reinforcement plate comes in various sizes and shapes to fit different types of reinforcement applications.

Moreover, the easy-install column reinforcement plate is made of high-strength material, ensuring the durability and resilience of the reinforcement system. This product is suitable for different types of buildings such as industrial plants, bridges, and high-rise towers.

Conclusion

In conclusion, cold deformation is an excellent alternative to traditional pipe bending that provides various advantages such as quality control, versatility, sustainability, and time and cost-efficiency. Moreover, the easy-install column reinforcement plate is a revolutionary product that improves the installation process of column reinforcement systems, making it easier, quicker, and more cost-effective.

If you are looking for reliable and accurate pipe bending services, contact us today and let us help you with your next project.